How to maintain pedestrian turnstiles

Pedestrian turnstiles are utilized regularly in our daily lives as a result of people’s growing security awareness and the social economy’s ongoing development. It is now more crucial than ever to maintain automatic turnstile gates. Today, we’d like to share some helpful ways to maintain the turnstile gates.

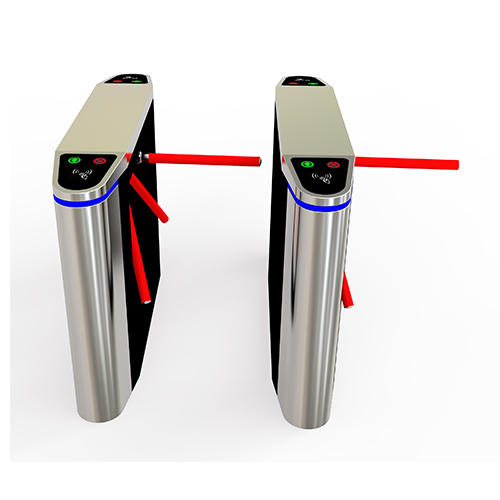

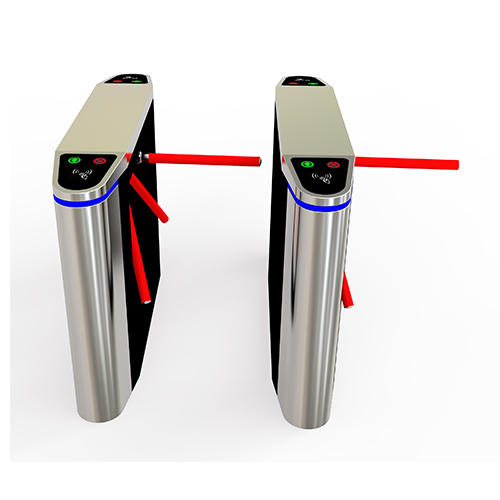

How to maintain tripod turnstiles and full height security turnstiles

Maintenance is crucial since it directly impacts the service life of tripod gates and full-height turnstile gates. The requirements must therefore be followed when performing routine maintenance. The majority of security turnstiles receive little to no maintenance, and users just swap out broken parts until they malfunction. As a result, over time, a few minor issues can snowball into major issues. Due to this, maintenance must be a priority for all users. The following should be considered when performing maintenance in general.

-

External maintenance

The majority of tripod turnstile gates and full-height turnstiles are constructed of SU304 stainless steel. Once a week, clean them up and get rid of any rust. Apply anti-rust oil to the chassis outside and polish it using a soft cloth and talcum powder. To preserve the anti-rust action, wait until the anti-rust oil has naturally dried for 3 to 5 hours before rubbing it. Clean up any surface dust from the painted chassis before touching up any exposed scratches with the same color paint.

-

Movement maintenance

The machine’s movement is the beating heart of the turnstile machine, so it needs to be well-maintained. It is typically maintained once a month. Cut off the power, remove the upper cover, brush off any dust, then clean the transmission component before adding butter or high-concentration engine oil. If any fasteners are loose, make sure you tighten them. If there is a gap of more than 3mm, the normal gap (1-1.5mm), then replace the positioning arm and the positioning plate. Check the wear of the sensitive sections. To reduce resistance and lubricate the solenoid valve when it moves left and right, the solenoid valve core must be adequately fed with butter or motor oil. Add just enough, but not too much.

-

Circuit maintenance

Look for any issues with the electronic control components based on previous usage. If everything is okay, wrap the power supply if it is exposed, organize the power cable, and replace the cable if it is aging. Check the specifications of each component by consulting the handbook. In the event of issues, it is required to identify the issue’s root cause and replace certain electronic parts.

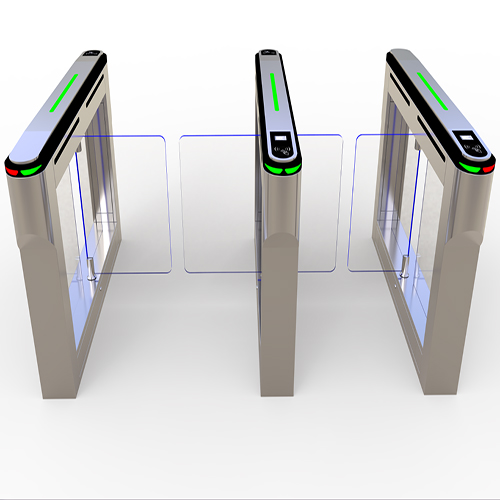

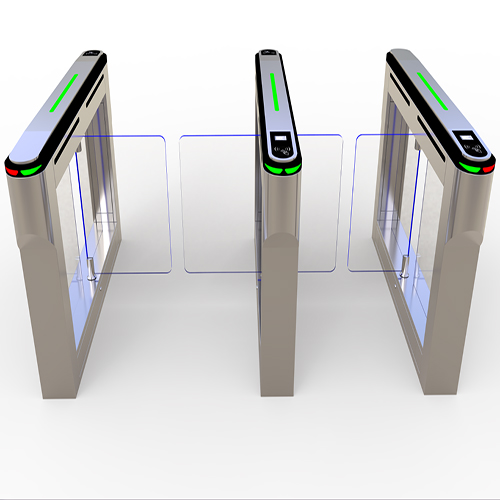

How to maintain optical swing turnstiles & speed turnstile gates

-

The chassis maintenance

Swing gate turnstiles’ and speed turnstiles’ chassis are made of an electrolytic board (A3 board) or SU304 stainless steel, which are sprayed or painted on them. After a while, the stainless steel chassis will develop surface rust patches. Sand them with talcum powder, green gauze, and sandpaper to avoid altering their appearance. Then, polish the mirror’s surface with a polishing wheel and polishing wax to make it look shiny. If necessary, apply anti-rust paint to the surface. Dust should be removed from the painted or sprayed chassis with a soft cloth. Use the same color paint to cover any scratches on the surface. Keep in mind not to paint where you will be fixing photocells. The swing gate will falsely alarm once a cover is placed over it, causing unnecessary hassle.

-

The movement maintenance

Turn off the power, remove the lid, and sweep the dust from the surface. Spray butter on the transmission component, take the swing gate motor out, rub the butter into the gear and wheel grooves, and then replace the motor in its original location. If the connecting piece’s bolts are loose, look over them and tighten them. Limit switches and limit metal sheets should never be adjusted carelessly. Their gap should be 1-2mm. If it is too far away, it won’t be sensed, and if it is too close, it will be easily harmed.

-

Circuit maintenance

Disconnect the power source, clean off the surface, install the plug-ins, and tighten them if necessary; do not arbitrarily relocate the wiring. Immediately cover the external power supply if it is exposed, and quickly fix it if there is a leak. To determine whether the technical parameters of the interfaces at either end are normal, consult the manual, and repair worn-out electrical components as soon as possible.

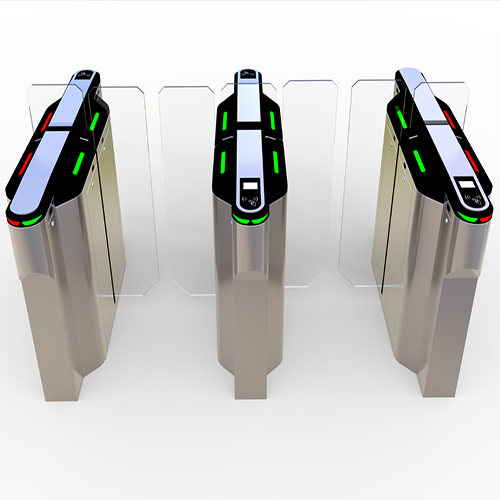

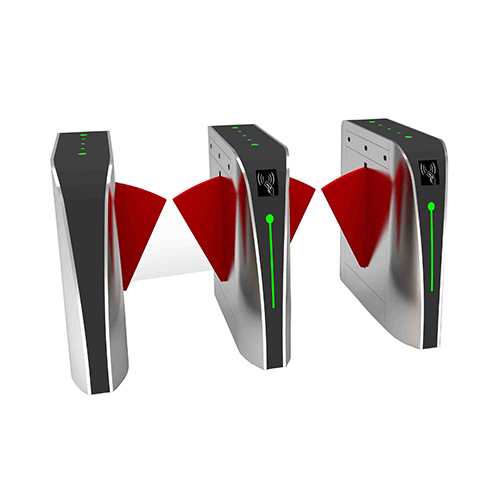

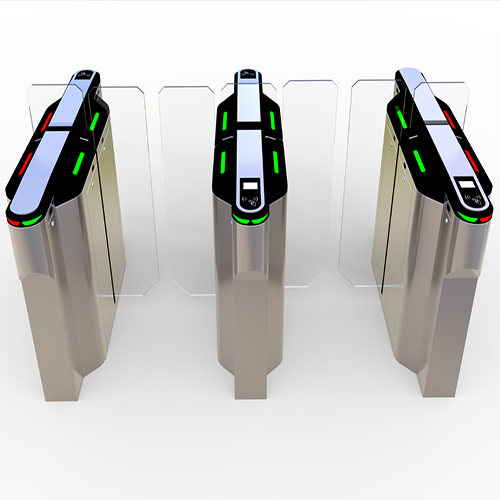

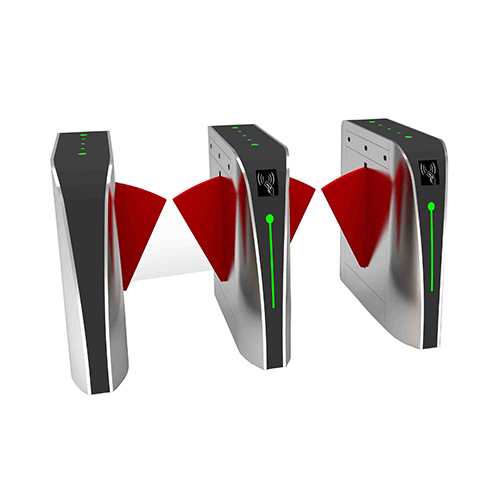

How are the optical flap turnstiles and sliding turnstiles maintained?

The following issues need to be taken into consideration when maintaining a flap turnstile gate, which is similar to maintaining a swing gate.

-

Chassis maintenance

The flap gates’ and sliding turnstile gates’ chassis are constructed from SU304 stainless steel or electrolytic board (A3 board) that has been painted or spray-coated. After some time, the stainless steel chassis will develop surface rust patches. Sandpaper, green gauze, and talcum powder should be used to clean them. Use a polishing wheel and polishing wax to polish the mirror surface. If necessary, treat the surface with anti-rust paint. Wipe the sanded surface with long lines (to prevent thick lines Orientation). Dust should be removed from the painted or sprayed chassis with a soft cloth. Use the same color paint to cover any scratches on the surface. Keep in mind not to paint where you will be fixing photocells. The flap barrier gate will falsely alarm once a cover is placed on it, causing unnecessary hassle.

-

The movement maintenance

Open the cover, turn off the power, and wipe off the surface’s dust. Butter should be sprayed on the transmission component, the motor should be removed, butter should be put in the grooves of the gears and wheels, and then the motor should be put back in place. Do not casually adjust the limit switch and the limit metal sheet; tighten the connection piece’s screws if they are loose. A spacing of 1-2mm is ideal. It will not be detected if it is too far away, and if it is too close, it will be readily harmed.

- Circuit maintenance

Disconnect the power source, clean off the surface, install the plug-ins, and tighten them if necessary; do not arbitrarily relocate the wiring. Immediately cover the external power source if it is exposed, and quickly fix it if there is a leak. To determine whether the technical parameters of the interfaces at either end are normal, consult the manual, and repair worn-out electrical components as soon as possible.

Double Lane Full Height Turnstile Gate for Residential Area

Double Lane Full Height Turnstile Gate for Residential Area

Dual Lane Tandem Full Height Turnstile Gate for Industry Park

Dual Lane Tandem Full Height Turnstile Gate for Industry Park

Single Full Height Security Turnstile for Office Buildings

Single Full Height Security Turnstile for Office Buildings

Motorised Double Full-Height Turnstile for Office Buildings

Motorised Double Full-Height Turnstile for Office Buildings

Please leave a message if you are interested in this model